Chopped Fiber

More products

More products

More products

More products

Labon's extensive range of pulp products includes various grades, from low-end to high-end, offering wet pulp and dry pulp with different fiber lengths and degrees of fiberization.

We have the most comprehensive portfolio of pulp products in the market and provide customized solutions for numerous applications, meeting diverse customer needs.

Transmission belts

Heavy-duty tires

Reinforced rubber

Gaskets

• Improving tensile strength of rubber at high temperatures

• Increasing rubber modulus

• Enhancing tear resistance of rubber

• Improving wear resistance and puncture resistance of products

Adhesives

Sealants

Coatings

• Improving thixotropy and filling reinforcement

• Thickening or increasing viscosity

• Strong temperature tolerance

Spiral wound gaskets

Compressed gaskets

• Enhancing gasket strength

• Providing chemical stability in corrosive media

• Providing thermal stability in corrosive media

• Low creep

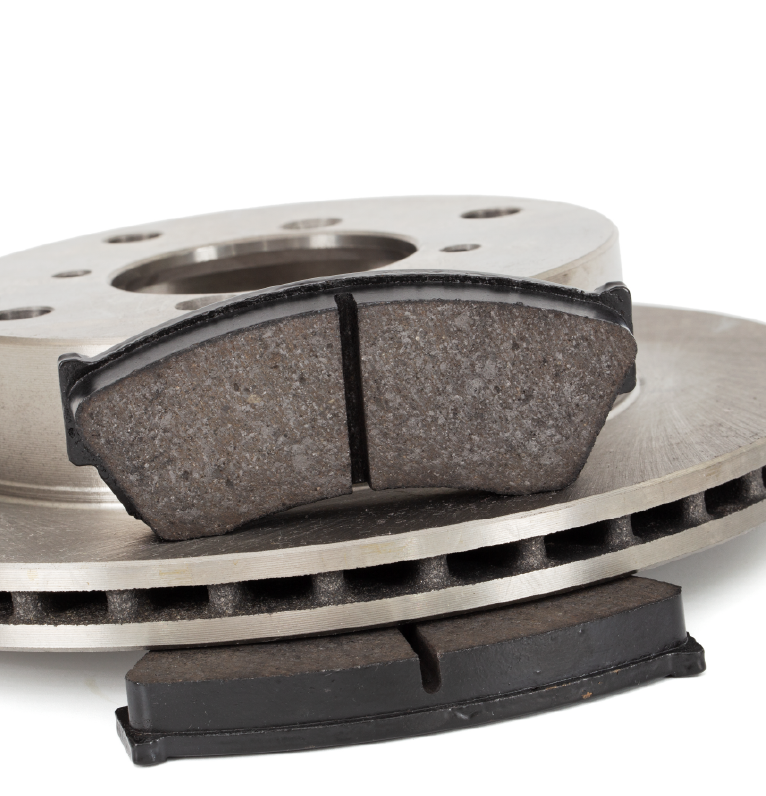

Dry Friction Materials:

Brake Pads - Automotive/Commercial Vehicles/Rail Transportation

Wet Friction Materials:

Clutch Facings

• Preformability: Providing "green strength" and filler adhesion.

• Offering matrix reinforcement: Especially at high temperatures (higher sheet strength and integrity for brake pads; reduced edge debris).

• Providing wear resistance: Aramid pulp contributes to reduced brake pad wear.

• Reducing noise and judder during braking: Aramid pulp helps reduce both effects.

• Aramid pulp does not form a film on the brake pad surface (aramid carbonizes at high temperatures, not melt).